The Blueprint for Future-Proof Connectivity

Fiber optic network installation is the process of deploying optical fiber cables to transmit data as light pulses. This technology offers superior speed and reliability over traditional copper by using a principle called total internal reflection, where light travels through a glass core protected by cladding that reflects the light inward, preventing signal loss and electromagnetic interference.

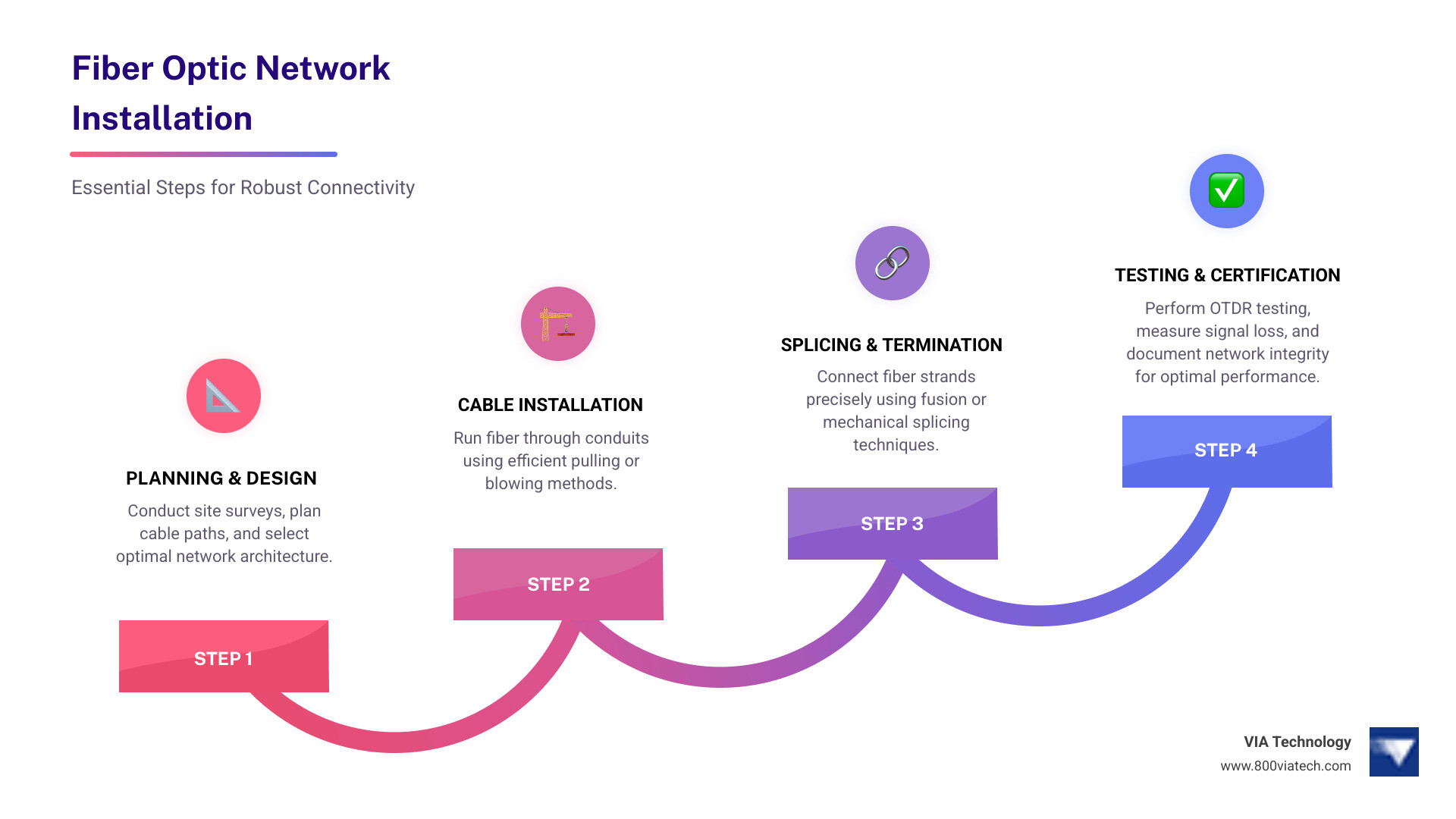

Quick Overview: Fiber Optic Network Installation Process

- Planning & Design - Site survey, cable path planning, network architecture selection

- Cable Installation - Running fiber through conduits using pulling or blowing methods

- Splicing & Termination - Connecting fiber strands using fusion or mechanical splicing

- Testing & Certification - OTDR testing, insertion loss measurement, documentation

Unlike copper cables that use electrical signals, fiber optics enable faster speeds over longer distances with greater bandwidth. For construction companies and businesses with complex IT projects, this means best reliability and security. The technology is immune to electrical interference, provides greater bandwidth, and offers superior data protection.

As Manuel Villa, President and CEO of VIA Technology, I have specialized in low-voltage cabling and fiber optic network installation for decades, managing complex IT infrastructure for organizations like the City of San Antonio and University Health Systems.

Why Fiber Optics are Essential for Modern Construction and Business

For modern construction projects and businesses, a fast, reliable, and secure network is non-negotiable. Fiber optics outperform traditional copper cabling in every key metric, making them the essential choice for future-proof operations.

Key advantages of fiber optics include:

- Higher Bandwidth & Faster Speeds: Fiber offers a massive data capacity, supporting complex applications and numerous devices simultaneously. With speeds up to 100 Gbps and beyond, it enables lightning-fast data transfer for cloud services and large project files.

- Longer Distances: Fiber optic signals travel significantly farther than copper without degradation, making it ideal for large campuses, connecting multiple buildings, or linking remote sites.

- Improved Security: Since fiber transmits light, it emits no electromagnetic signals, making it extremely difficult to tap without detection. This is a critical advantage for businesses handling sensitive information.

- EMI Immunity: Fiber is immune to electromagnetic interference from power lines or heavy machinery, ensuring reliable performance in noisy industrial or data center environments.

- Scalability & Future-Proofing: Fiber networks are easily upgraded to handle future bandwidth demands, ensuring your infrastructure can grow with your business.

| Feature | Fiber Optic Cable | Copper Cable (e.g., Cat6) |

|---|---|---|

| Speed | Up to 100 Gbps (and beyond) | Up to 10 Gbps (over shorter distances for Cat6) |

| Bandwidth | Extremely high, virtually limitless | Limited, susceptible to distance and interference |

| Distance | Hundreds of kilometers (single-mode) | 100 meters (for 1 Gbps Cat6), much less for higher speeds |

| Security | Very difficult to tap, no electromagnetic emissions | Susceptible to electromagnetic tapping, radiated signals |

| Interference | Immune to EMI | Highly susceptible to EMI |

| Reliability | Highly reliable, less signal loss | Can be affected by external factors, more signal loss |

| Cost | Higher initial installation, lower long-term maintenance | Lower initial installation, higher long-term maintenance |

| Size/Weight | Thinner, lighter, less space-consuming | Thicker, heavier, takes up more space |

Single-Mode vs. Multi-Mode Fiber: Choosing the Right Cable

During a fiber optic network installation, a key decision is choosing between single-mode and multi-mode fiber.

- Single-Mode Fiber (SMF) has a very small core (8–10 microns) that allows a single light path, typically from a laser source. This focused path enables data to travel over extremely long distances (kilometers) with minimal signal loss, making it ideal for connecting buildings across a campus or linking distant data centers.

- Multi-Mode Fiber (MMF) has a larger core (50 or 62.5 microns) that allows multiple light paths, often from LEDs or VCSELs. This design is best for shorter distances, such as within a single building, in data centers, or for local area networks (LANs). It is often a more budget-friendly option for these applications.

The choice depends on the required distance and bandwidth. We help determine the best fit for your specific project needs.

Common Business Applications

Fiber optics are the backbone for numerous industries:

- Data Centers: Require maximum speed and bandwidth for server-to-server communication and external connectivity.

- Industrial Automation: Provides reliable, interference-immune control and monitoring for machinery in electrically noisy environments.

- Telecommunications: Forms the foundation of high-speed internet, TV, and phone services.

- Large Office Buildings & Campuses: Connects departments and buildings over large areas without signal degradation.

- Healthcare Facilities: Ensures fast, secure transmission of patient data, medical images, and real-time monitoring.

- Government Projects: Provides secure and reliable communication for critical infrastructure.

- Construction Industry: Supports data-intensive IoT devices, surveillance, and temporary offices on modern job sites. The Impact of IoT on Network Design makes fiber an ideal choice for these demanding environments.

Planning and Design: The Foundation of a Successful Fiber Optic Network Installation

A successful fiber optic network installation is built on meticulous planning and expert design. This foundational phase ensures your network meets current needs and is prepared for future growth.

Our process begins with understanding your business goals to build a robust solution. Key steps include:

- Site Survey: A thorough assessment of existing infrastructure, potential obstacles, and environmental factors to map out optimal cable routes.

- Cable Path Planning: Determining the most efficient and secure routes, whether aerial or underground, and identifying building entry points while avoiding sharp bends or damage-prone areas.

- Network Architecture Selection: Collaborating to choose the right model, such as Fiber to the Building (FTTB), Direct Fiber, or Shared Fiber (AON/PON), to match your operational and bandwidth requirements.

- Adhering to Standards: We strictly follow industry guidelines from organizations like The Fiber Optic Association (FOA) to guarantee safety, reliability, and performance.

- Project Budgeting: Providing a detailed estimate of all components and labor to align the project with your financial expectations.

Key Considerations for Your Fiber Optic Network Installation Plan

Every project has unique challenges that we address in the planning phase:

- Aerial vs. Underground Installation: We weigh the costs, security, and environmental factors of running cables on poles versus burying them in protective conduits.

- Conduit Requirements: Conduits shield fiber from physical damage and moisture. We select the correct type and size, sometimes using microducts to simplify future upgrades.

- Bend Radius and Pulling Tension: Fiber cables have strict limits on how much they can be bent or pulled. Our plans ensure gentle routes and proper installation techniques to prevent damage.

- Environmental Factors: We select appropriate cable types (e.g., armored fiber optic cable) and protective measures to withstand temperature changes, moisture, and UV exposure.

- Integrating with Existing Infrastructure: We design seamless transitions between new fiber and existing copper or wireless networks to minimize disruption, which is crucial as the Internet of Things is Revolutionizing Facilities Management.

Factors Influencing Installation Costs

The overall cost of a fiber optic network installation depends on several factors:

- Cable Type and Length: Single-mode, multi-mode, or armored cable costs vary, as does the total distance required.

- Labor Costs: Installation requires certified technicians with expertise in planning, splicing, and testing.

- Site Complexity: Projects involving excavation, horizontal drilling, or navigating complex existing infrastructure are more resource-intensive.

- Required Permits: Obtaining permits for work in public rights-of-way can add to the project timeline and cost.

- Specialized Equipment: The use of fusion splicers, OTDRs, and other precision tools is factored into the project cost.

- New Construction vs. Retrofit: Installing fiber in new construction is typically more straightforward than retrofitting an existing, operational building.

The Installation Process: From Cable Pulling to Splicing

With a solid plan, the physical fiber optic network installation begins. This phase demands precision and expertise to build a network with lasting integrity and performance.

The installation involves several key stages:

- Cable Preparation: We inspect cables for defects, cut them to precise lengths with adequate slack, and carefully strip the outer sheaths to expose the individual fibers. The glass strands are then cleaned with specialized solutions to ensure a pristine surface for connection.

- Cable Installation: For indoor or conduit runs, we use cable pulling techniques with equipment that ensures tension is evenly distributed and within safe limits. For long-distance or underground runs, the blowing method uses compressed air to propel the cable through a conduit, reducing stress and speeding up the process.

- Cable Management: Cables are carefully routed, secured with appropriate ties, and clearly labeled. This organization is critical for long-term reliability and simplifies future maintenance.

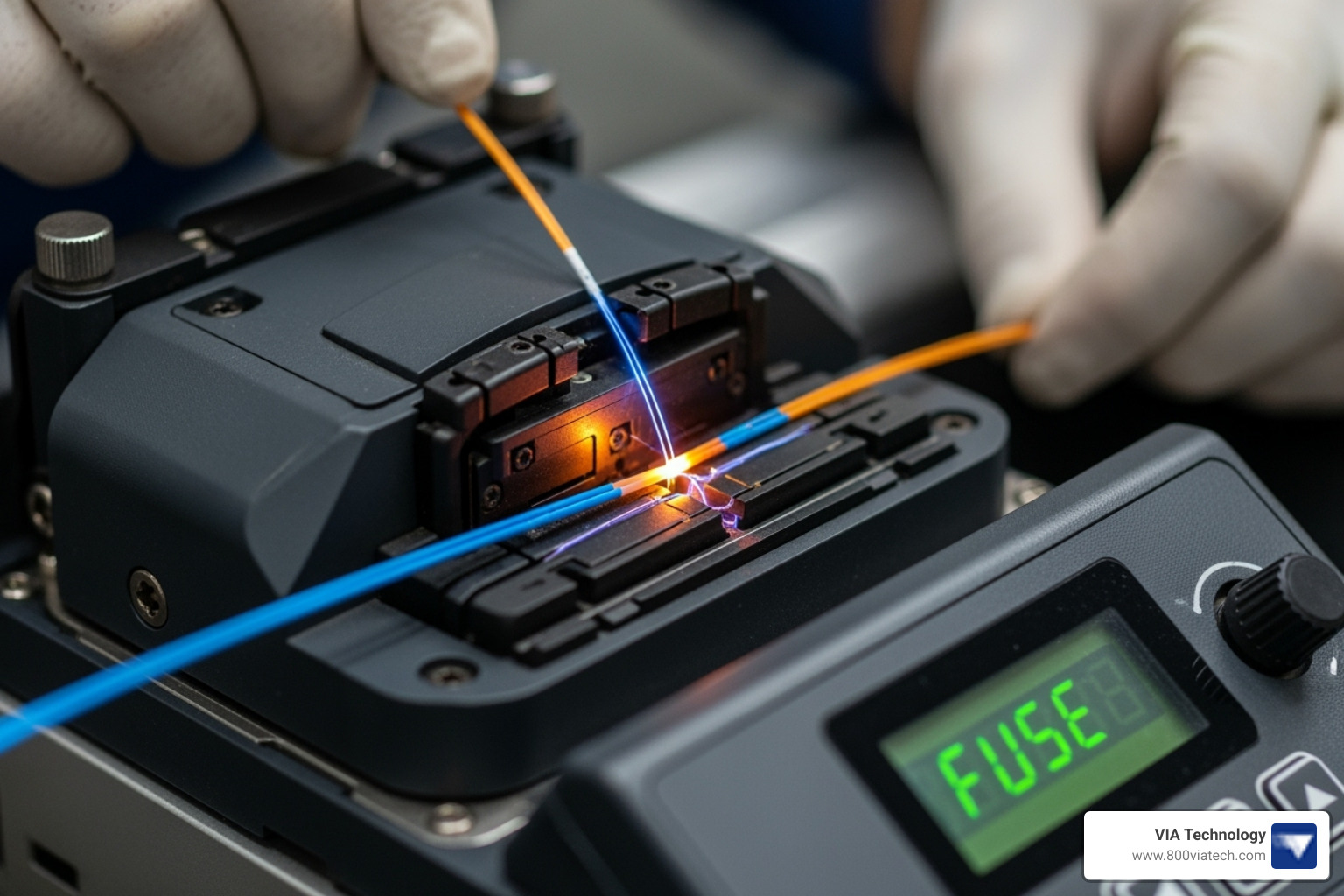

The Art of Fiber Optic Splicing

Splicing, the process of permanently joining two fiber optic cables, is critical to network performance. An imperfect splice can cause significant signal loss (attenuation) and degrade reliability.

- Fusion Splicing: This is the gold standard. A fusion splicer precisely aligns two fiber ends and uses an electric arc to melt them into a seamless joint. This method creates a permanent, low-loss connection ideal for critical backbone links.

- Mechanical Splicing: This method uses a mechanical connector to align and hold two fibers together. It is faster and does not require a fusion splicer, making it useful for temporary or quick repair scenarios, though it typically results in higher signal loss.

- Pigtail Splicing: This technique involves fusion-splicing a pre-terminated fiber "pigtail" (a short cable with a connector on one end) onto a longer fiber run. It combines the quality of a fusion splice with the convenience of a standard connector.

Across all methods, clean connections are paramount. Our technicians use inspection scopes and cleaning tools to ensure every connection point is free of contaminants.

Overcoming Common Fiber Optic Network Installation Challenges

Even with careful planning, challenges can arise. Our experience allows us to mitigate these common issues:

- Cable Damage During Pulling: We prevent damage by using proper equipment, monitoring tension, and adhering to the cable's specified pulling limits. The blowing method is often used to reduce physical stress.

- Exceeding Bend Radius: Bending a cable too sharply causes signal loss. We plan routes with gentle curves and use appropriate hardware to maintain the minimum bend radius.

- Contamination at Connection Points: Dust or oils on a fiber end-face can block the signal. We enforce strict cleaning and inspection protocols for every connection.

- Incorrect Termination: Improperly attached connectors cause high signal loss. We use precise techniques and test every connection immediately to verify its integrity.

- Environmental Factors: We select outdoor-rated or armored cables and use proper conduit protection to shield the network from temperature, moisture, and UV damage.

Testing and Certification: Ensuring Network Performance and Reliability

After installation, rigorous testing and certification are performed to verify that the network delivers the required high-speed, reliable connectivity. This step proves the quality and performance of the fiber optic network installation.

Our verification process includes several key tests:

- Post-Installation Verification: We check each link for continuity and correct polarity, ensuring all connections are clean and properly seated.

- Insertion Loss (IL) Testing: This measures the total signal loss across a fiber link, including all connectors and splices. Low IL values are essential for strong, clear signal transmission.

- Optical Return Loss (ORL) Testing: This measures the amount of light reflected back toward the source. High reflections can disrupt network performance, so low ORL values indicate a clean, efficient connection.

Upon successful completion of all tests, we provide Certification and Documentation. This package includes comprehensive test results and link maps, serving as proof that your network meets industry standards and providing a valuable baseline for future maintenance or troubleshooting.

The Critical Role of OTDR Testing

An Optical Time-Domain Reflectometer (OTDR) is an essential tool for characterizing a fiber optic cable. It sends a light pulse down the fiber and analyzes the reflected signal to create a detailed "picture" of the entire link.

OTDR testing is used to:

- Locate Faults: Pinpoint the exact location of issues like tight bends, bad splices, or breaks, which dramatically speeds up troubleshooting.

- Measure Signal Loss: Quantify the loss (attenuation) at specific points, such as splices and connectors, to ensure they meet design specifications.

- Verify Splice Quality: Confirm that each fusion splice has minimal loss, ensuring a robust connection.

OTDR testing provides an objective record that the fiber optic network installation complies with all performance standards, guaranteeing your investment delivers on its promise of reliability.

Frequently Asked Questions about Fiber Optic Installation

Here are answers to common questions about fiber optic network installation for businesses and construction projects.

What are the main differences between aerial and underground fiber installation for a business campus?

The choice between aerial and underground installation involves a trade-off between cost, speed of deployment, and long-term reliability.

- Aerial Installation: Cables are strung on utility poles. This method is generally faster and has a lower initial cost. However, the cables are exposed to weather, falling tree branches, and potential vehicle damage, making them less reliable long-term.

- Underground Installation: Cables are placed in protective conduits buried via trenching or horizontal drilling. While this has a higher upfront cost and takes longer, it offers far superior protection from weather and physical damage, resulting in a more secure and reliable network.

For most business campuses and new construction, we recommend underground installation for its improved security and longevity.

Why is professional installation critical for fiber optic networks?

Professional installation is essential for a reliable fiber optic network installation due to the technology's unique requirements:

- Specialized Tools and Expertise: Handling delicate glass fibers requires precision tools like fusion splicers and OTDRs, along with certified technicians who know how to use them.

- Technical Limits: Professionals understand and adhere to strict bend radius and pulling tension limits to prevent irreversible damage to the fiber.

- Proper Splicing and Termination: Imperfect connections cause signal loss (attenuation) that degrades network performance. Experts ensure every connection is clean and robust.

- Warranty and Certification: Professional installers certify that the network meets industry standards and provide a warranty for their work, ensuring long-term performance and peace of mind.

How does fiber optic technology improve network security?

Fiber optics offer inherent security advantages over traditional copper cabling:

- Immunity to EMI Tapping: Fiber transmits light and does not radiate electromagnetic (EMI) signals that can be intercepted. Copper cables, which use electrical signals, can be tapped passively from a distance.

- Difficult to Tap Physically: Accessing data on a fiber cable requires physically cutting into the glass, an intrusive act that is difficult to perform covertly and would cause an immediate, detectable network outage. A passive copper tap can go unnoticed.

Because the data signal is contained entirely within the glass core, fiber is the preferred choice for government, finance, and any business handling sensitive information.

Conclusion: Powering Your Business with a Robust Fiber Network

In modern business and construction, a high-performance network is the engine for success. A professional fiber optic network installation delivers the speed, reliability, and security that legacy copper systems cannot match, future-proofing your operations against growing data demands.

From meticulous planning and design to precision splicing and rigorous testing, every step is critical to building a robust network. The result is a system that can handle massive data flows, connect teams across large campuses, and protect your sensitive information.

At VIA Technology, we have decades of experience managing complex IT, IoT, and construction projects across Texas. We partner with you from initial design to ongoing support, ensuring your fiber optic network installation is done right and serves your business for years to come.

Don't let outdated technology limit your potential. Accept light-speed connectivity to keep your operations online, fast, and secure.